Add to Cart

Custom Precision Investment Casting Stainless Steel OEM Service

Product Description

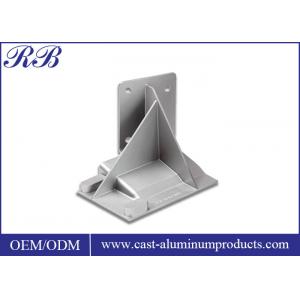

| Material | Cast Stainless Steel |

| Casting Process | Investment Casting |

| Inspections | Based on finished drawings |

| Minimum Order Quality | 100Pcs |

| Mould & Samples | about 30days after getting order |

| Payment Terms |

of mold: 50% advance payment, 50% after sample approval. of mass production: 50% advance payment, 50% before deliver |

Foundry Overview

We focus on the production of metal casting products. The existing production equipment includes aluminum alloy die-casting machine, grinding and polishing machine, drilling and tapping machine, vibrating machine, CNC lathe, etc., providing "mold design---mould making---casting production --- Post-processing surface treatment" one-stop service.

We are the source manufacturer, which can effectively control costs and strictly control quality and delivery.

Our casting products are widely used in various industries, such as: electrical accessories, industrial machinery parts, automobile and motorcycle parts, etc.

1.Good quality with direct factory price

3. OEM / ODM Service

4.Customized size and specification as per your drawing or sample

5. Quotation will be offered within 72 hours.

6. Flexible lead time& efficient shipment.

7. Advanced Production & Measurement equipment

8.Files Available: 2D (.dxf / .dwg / .pdf ) and 3D (.igs / .stp / .x_t )

OEM Service:

• Tooling Design & Manufacture + Casting + Machining + Surface Treatment;

Casting Process:

• Gravity Casting

• Die Casting

• Low pressure Die Casting

• Investment Casting

Surface Treatment:

• Different finishing, such as Anodizing, Tumbling, Chromating, Polishing, Painting, Powder coating, Electroplating;

How To Order

To receive accurate cost and time estimates for your custom casting project, please provide the following information of the parts you are requesting,

• 2D Drawings(.pdf), 3D(.igs)and specifications:

including but not limited to material, dimensional tolerance, machining requirements, actual or estimated weight and inspection requirements.

• Material: a specific metal grade or the preferred material and desired properties.

• Quantity: Include the anticipated volume, both present and future. Quantity has a large influence over production method, pattern development, and overall cost.

• Quality acceptance criteria, such as nondestructive test, mechanical testing are all critical considerations for a quote.

Investment (Lost Wax) Casting

Investment casting, also known as lost wax casting, is a precision casting process used to create metal parts from almost any alloy, and is typically used to create complex, thin-wall castings.

▪ Investment casting wax injection

▪ Assembly

▪ Investment casting shell building

▪ Dewaxing

▪ Investment castings metal casting pouring

▪ Knockout

▪ Cutoff

▪ Finish

| Advantages | Disadvantages |

|

• Excellent accuracy and flexibility of design. • Useful for casting alloys that are difficult to machine. • Exceptionally fine finish. • Suitable for large or small quantities of parts. • Almost unlimited intricacy. • Suitable for most ferrous/non-ferrous metals. • No flash to be removed or parting line tolerances. |

• Limitations on size of casting; • Higher casting costs make it imortant to take full advantage of the process to eliminate all machining operations. |